Any water that is used within a home travels through the homes main sewer line. The main sewer line will run outside the home and connects into a septic tank(s). Once wastewater enters the septic tank a separation process begins and should last a minimum of forty eight hours. This process allows for wastewater to be seperated into three different layers. All heavier solids will sink to the bottom of the septic tank known as the sludge layer. Fats, grease, oil, and any lighter debris will float to the top of the septic tank known as the scum layer. This leaves a layer in the middle of the tank that is the remaining water, also known as the clear or effluent layer. Once this separation is complete the effluent is able to leave the septic tank and continue on to the leach field. The effluent layer should be the only layer leaving the septic tank and being absorbed into the leach field. The scum and sludge layers will continue to accumulate as the years pass and it is imperative that homeowners have their septic tank pumped out every 3-5 years. The purpose of a septic tank pumping is to remove all sludge and scum before it accumulates to the point that those contaminants are able to exit the septic tank and enter into the leach field. If allowed to enter the leach field the sludge and scum will clog the pores of the soil in the leach field and inhibit the field from absorbing effluent efficiently. Once the leach field fails to absorb effluent it will have to be replaced.

Septic System Components and Maintenance

Septic systems are a vital component of a home and can be very costly to repair or replace. So it is important for homeowners to know how to perform basic maintenance procedures on their septic systems. By doing so will help ensure that a system operates as it was intended and will maximize the life of the system.

Other components that may exist in a septic system, include but are not limited to, septic tank filters, distribution box’s, pump chambers, control panels, shut off valves, and flushing valves. Not all of these listed components are present on every septic system. It is all dependent on the type of system present, and the installation design.

Septic tank filters are not present in all septic tanks, however, if a tank has a filter it is important that the filter is either cleaned or replaced every six months to a year. If a filter is not present, it is highly recommended that a homeowner has one installed. The filter’s job is to keep any debris that doesn’t fully separate out of the wastewater from leaving the septic tank and entering the leach field. Without a filter to restrict any sludge or scum from exiting a tank, a leach field is at risk of failing prematurely.

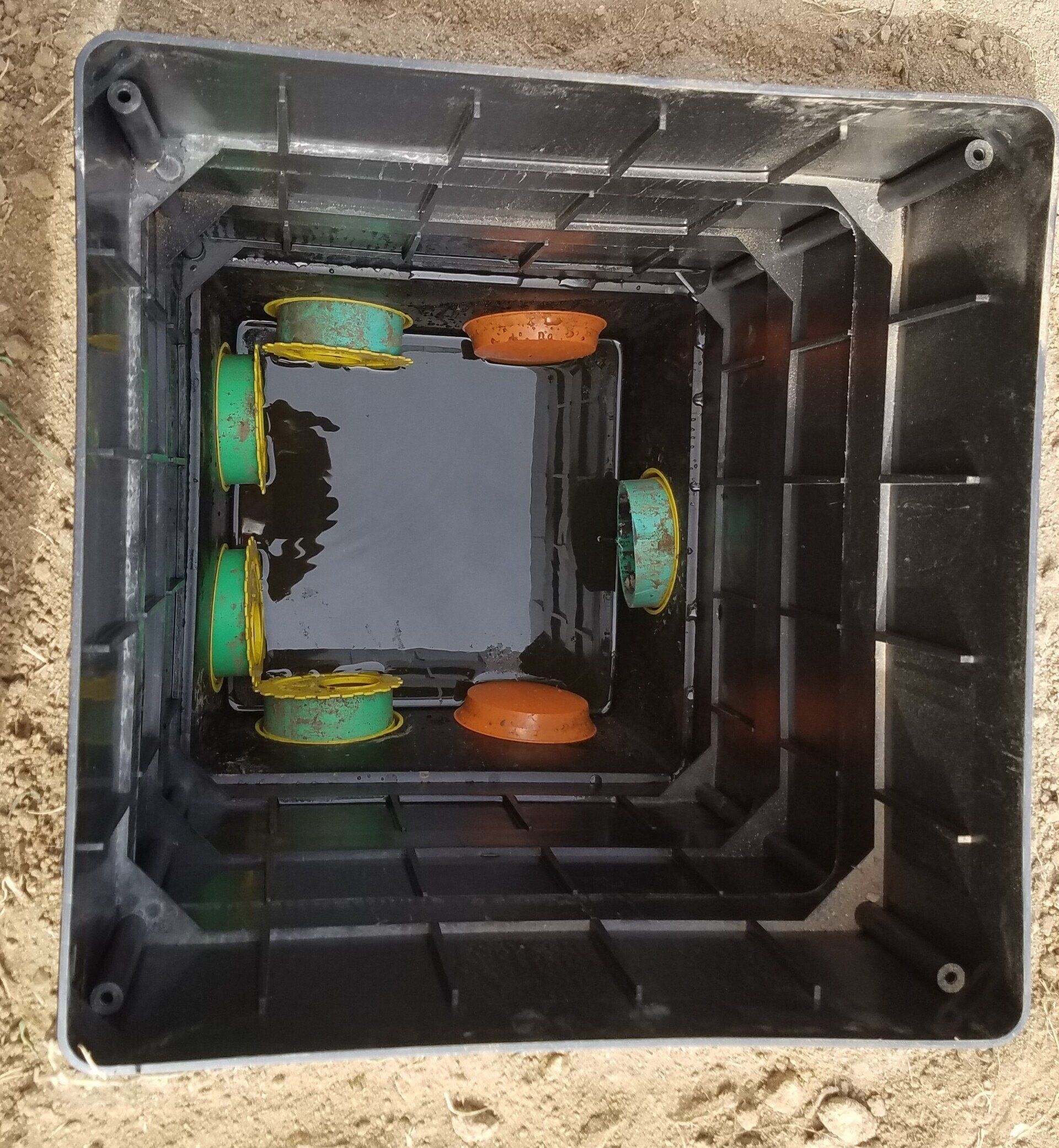

A distribution box, or d-box is simply either a plastic or concrete box with a lid. It’s purpose is to distribute the effluent from the tank into the leach field through multiple pipes. If a d-box is malfunctioning and not distributing the wastewater evenly to the exit pipes, then speed levelers can be installed and routinely inspected to ensure the flow is equal.

Some septic systems contain a secondary septic tank called a pump chamber, which houses a wastewater pump and the floats that control the pump. The pump chamber is installed after the septic tank and is designed to take on the wastewater that leaves the septic tank. Once the pump chamber is full the pump will turn on and deliver the wastewater to the leach field. When a homeowner has their septic tank pumped, it is recommended to have the pumper inspect the pump chamber to determine if it needs to be pumped out as well.

If a pump chamber is present then there should also be a control panel, or an alarm system present to indicate an issue inside the pump chamber. A control panel is able to manually or automatically control the pump. Control panels have built in alarm systems that will notify homeowners if the wastewater collecting inside the pump chamber is not being pumped to the leach field. If no control panel exists then an alarm system should still be present to alert homeowners of a problem in the pump chamber.

Some leach fields are designed with shut off valves that allow the homeowner to shut off sections of their leach field to allow a resting period. Allowing sections of a leach field the time to dry out can extend the life of a leach field. Recommended shut off and turn on intervals should be followed by the engineer who designed the septic system.

Engineered septic systems may also have flushing valves located at the end of a leach field. This allows homeowners the ability to flush out the pipes in their leach field with water. This will reduce the growth build up from the wastewater inside the pipes. If this maintenance step is ignored, the pipes in the leach field start to accumulate growth that blocks the holes in the pipe, which prohibits the wastewater from going through the holes and being absorbed into the soil evenly. Utilizing the flushing valves is a key component to maintaining a healthy leach field.

There are several different types of septic systems with varying working components. If a homeowner is ever unsure about their system, contact a septic professional for assistance. At Peak Septic Systems we also offer bi- annual routine maintenance plans. The maintenance plans are intended to relieve homeowners from the responsibility of maintaining their septic systems while still ensuring the system is running at its peak performance.